|

|

|

| Geared & Pull Push Type

|

|

|

|

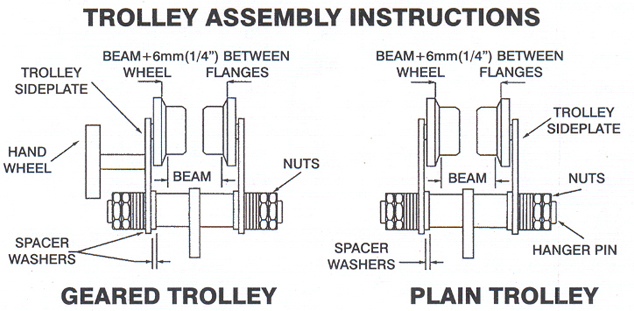

BECAUSE OF VARIATION IN BEAM WIDTHS, THE TROLLEY IS SUPPLIED WITH HANGER PIN AND SPACER WASHERS PACKED SEPARATELY.

ASSEMBLE AS FOLLOWS

1. Measure the actual width of the Runway Beam.

2. Assemble the required number of Spacer Washers equally to the inside of the Trolley Side Plates so that the dimension between Trolley Wheel Flanges is 6mm of 1/4" (Max) greater than the Runway Beam Width. Assemble the remaining washers outside the Trolley Side plate & fit Nuts to Hanger Pin. THERE MUST ALWAYS BE ATLEAST ONE WASHER ON THE INSIDE &THE OUTSIDE ON EACH TROLLEY SIDE PLATE (see diagram)

3. Slacken off the Hanger Pin Nuts & spread the Side Plates so that the wheels can be slipped up over the Runway Beam. Screw the Nuts firmly against the Washers, then suspend a light load from the Trolley to ensure that all four Wheels contact the Runaway Beam. Screw the Nuts tightly against the Washers than secure with Lockouts.

NUTS MUST BE TIGHT

4. Geared Trolley when assembled at the minimum beam width will require Hanger Pin to be offset, so it will not foul the Hand wheel.

5. Suspend the Maximum Safe Working Load from the Trolley then run the unit slowly along the full length of the Runaway to ensure satisfactory operation

| CAPACITY |

0.5t |

1t |

2t |

3t |

5t |

10t |

20t |

BEAMRANGE

STANDARD |

76-140 |

82-140 |

102-152 |

102-152 |

127-175 |

152-175 |

|

| OVERSIZE(1) |

64-152 |

64-203 |

88-203 |

102-203 |

114-203 |

125-203 |

136-203 |

| OVERSIZE(2) |

64-140 |

64-140 |

76-165 |

76-203 |

80-203 |

125-203 |

178-305 |

| OVERSIZE(3) |

68-94 |

68-100 |

94-124 |

116-140 |

142-180 |

142-180 |

|

| OVERSIZE(4) |

50-220 |

58-220 |

66-220 |

74-220 |

90-220 |

90-22 |

|

|

|

|

|

|

|