|

|

|

Meets

IS:2762/82 |

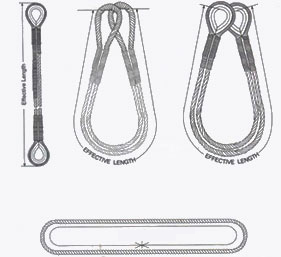

Double Part Basket

LT-GS-TE(1)

Double Part

Thimble Eye

LT-GS-LT(2)

Double Part Loop

LT-GS-TE(3)

Double Part Thumble

Groment Round

Circumference

|

| Grommets/Endless Slings Double Part 6x36 Const. IWRC 1960 N/mm'Grade FOS 1:8 |

| Size In |

Safe Working Loads in Tons |

| (mm) |

Straigt Pull |

Choker Hitch |

Basket Loads |

Vertical |

30o |

45o |

60o |

| 44 |

34 |

25 |

68 |

59 |

51 |

34 |

| 52 |

48 |

36 |

96 |

84 |

72 |

48 |

| 56 |

55 |

41 |

110 |

96 |

82 |

55 |

| 64 |

73 |

54 |

146 |

127 |

110 |

73 |

| 72 |

92 |

69 |

184 |

161 |

138 |

92 |

| 76 |

103 |

77 |

206 |

180 |

154 |

103 |

| 80 |

114 |

85 |

228 |

199 |

171 |

114 |

Note: This table is based on FOS 1:8 of Rope results multiplied by

2 times = Safe Working Load of complete Sling. |

|

| Grommets/Endless Slings Double Part 6x36 Const. IWRC 1960 N/mm2 Grade FOS 1:6

|

| Size In |

Safe Working Loads in Tons |

| (mm) |

Straigt Pull |

Choker Hitch |

Basket Loads |

Vertical |

30o |

45o |

60o |

| 44 |

45 |

33 |

90 |

78 |

67 |

45 |

| 52 |

64 |

48 |

128 |

112 |

96 |

64 |

| 56 |

74 |

55 |

148 |

129 |

111 |

74 |

| 64 |

96 |

72 |

192 |

168 |

144 |

96 |

| 72 |

120 |

90 |

240 |

210 |

180 |

120 |

| 76 |

137 |

102 |

274 |

239 |

205 |

137 |

| 80 |

152 |

114 |

304 |

266 |

228 |

152 |

Note: This table is based on FOS 1:6 of Rope results multiplied by

2 times=Safe Working Load of complete Sling. |

|

| Rope for Grommets/Endless Slings 6/37 Const. F. C. or IWRC with T/St 1770 N/mm2 (General Information)

|

| Size Inches |

Minimum Cirucumf.(Ft).

|

Safe Working Loads in Tons |

Straight Pull |

Choker Hitch |

Basket Loads |

Vertical |

30o |

45o |

60o |

| 1/4 |

6 |

0.92 |

0.69 |

1.8 |

1.6 |

1.3 |

0.92 |

| 3/8 |

6 |

2.0 |

1.5 |

4.0 |

3.5 |

2.9 |

2.0 |

| 1/2 |

8 |

3.5 |

2.6 |

7.0 |

6.1 |

5.0 |

35 |

| 5/8 |

8 |

5.4 |

4.0 |

11.0 |

9.4 |

7.6 |

5.4 |

| 3/4 |

10 |

7.6 |

5.7 |

15.0 |

13.0 |

11.0 |

76 |

| 7/8 |

10 |

10.0 |

7.6 |

20.0 |

17.0 |

140 |

10.0 |

| 1 |

12 |

13.0 |

9.7 |

26.0 |

22.0 |

180 |

13.0 |

| 1 1/8 |

12 . |

15.0 |

11.0 |

31.0 |

26.0 |

22.0 |

150 |

| 1 1/4 |

16 |

18.0 |

14.0 |

36.0 |

32.0 |

260 |

18.0 |

| 1 3/8 |

16 |

22.0 |

16.0 |

44.0 |

38.0 |

31.0 |

22.0 |

| 1 1/2 |

20 |

26.0 |

19.0 |

52.0 |

45.0 |

360 |

26.0 |

| 1 3/4 |

20 |

34.0 |

26.0 |

68.0 |

60.0 |

49.0 |

34.0 |

| 2 |

24 |

44.0 |

33.0 |

88.0 |

76.0 |

620 |

44.0 |

| 2 1/4 |

24 |

54.0 |

41.0 |

108.0 |

940 |

77.0 |

54.0 |

|

|

System for Grommet Slings

1) Grommet Slings can be fabricated in very short circumferences. The reason is this: grommet Slings are made from one continuous length of strand or wire rope. This requires only one tuck-in point as compared with the six luck-points needed to manufacture an endless sling.

2) A grommet consists of an endless rope having 6/1 construction & is used where high ultimate breaking strength of the rope is required beyond the limits of a single part rope.

3) A strand of sufficient length to complete the grommet shall be obtained by either of the following methods:

Method A: An outer strand shall be unlaid from a specimen of 6/1 rope conforming to the requirement of the customer.

Method B: Unlaying from a specimen of 6/4 rope having strand in all respects equivalent to those obtained by method A above.

Method C: Using a virgin strand either performed or post formed & in all other respects equivalent to those obtained by methods A & B

4) During the courses of construction of a grommet the preformed lay of the strand shall be maintained & shall be interfered with except when laying in the core of which purpose length of strand left to form the core should be straightened.

5) The length of the strand required to form a grommet shall be equal to about 7.5 times the perimiter of the grommet in case of spliced grommet, but in case of complete streamline spicing lenght shall be 4 times the effective length.

|

|

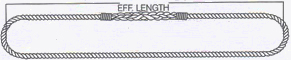

Endless Slings Endless Slings

System for Endless Slings

Butt Splice: The Two Ends Of The Rope Shall Be Joined Together By Two Five-tuck Splices

Number Of Tucks: The splices be tucked three times with full size of the strand, a fourth time with the

strands each reduced to half the original number and a fifth tome with the strands each further

reduced to one third the original number. The heart strand is to be rowed in during tucking so that a double heart is produced for at least the length of the first three tusks in both directions.

Method Of Tucking: The tucks of the splice shall be made over one strand and under one strand against the lay of the rope. The heart strand of the rope shall not be removed when the strands are opened out for tucking, but may be cut to a suitable length.

Finishing of the Splice: On completion of tucking, the rope shall be stretched and the ends of all wires, including those which have to be laid back and stopped down, shall be broken off close in the nip of the lay of the rope by twisting.

Finishing: The ends fo the splice in way of twisted-off ends of wire, that is between the end and the third, tusk, shall be tightly served with seizing wire, after parceling with canvas, hessian or wax paper.

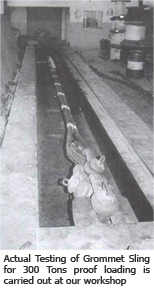

"We know Sling making come to us, We have expert team of Splicers"

|

|

Note: In the interest of constant research & development we reserve the right to change the design & specifications without notice. |