|

|

|

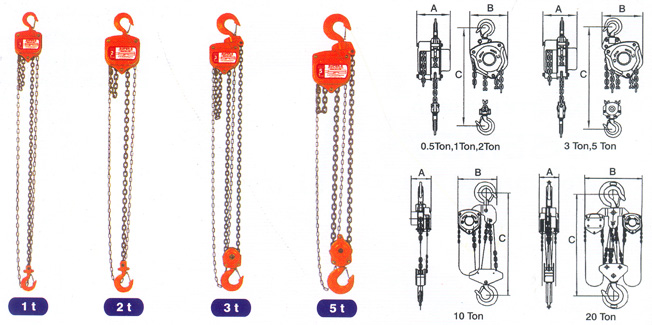

SUPER-8 Chain Hoist S-Series

Ultra Headroom Cmpact Design Chain Hoist (S-Series)

|

|

|

Ultra S-series

The ULTRA S- Series Chain Hoist is a portable lifting device easily operated by hand chain. It is suitable for use in factories, mines, farms, construction sites, wharves, docks and warehouses for installation of equipment, as well as for loading and unloading goods. It is specially advantageous for lifting work in the open air and places where no power supply is available.

ULTRA S- Series Chain Hoist has some improvements in construction design and using material and manufacturing process. It sells well at home as the construction of materials JIS standards and in light weight.

The chain Hoist can be attached to a trolley of any as a traveling chain Hoist. It is suitable to monorail overhead conveying system, hand traveling crane and jib crane.

| Capacity |

tons |

1 |

2 |

3 |

5 |

10 |

20 |

| Standard lift |

m |

3 |

3 |

3 |

3 |

3 |

3 |

| Running test load |

Kn |

15 |

30 |

45 |

75 |

15 |

30 |

| Effort required to lift max. load |

N |

309 |

360 |

340 |

414 |

414 |

4 14X2 |

| No of colums of load chain |

|

1 |

1 |

2 |

2 |

4 |

8 |

| Load chain diameter |

mm |

6 |

8 |

8 |

10 |

10 |

10 |

| Dimensions |

A |

140 |

161 |

161 |

186 |

207 |

215 |

| |

B |

158 |

187 |

210 |

253 |

398 |

650 |

| |

C |

317 |

414 |

465 |

636 |

798 |

890 |

| Net weight |

kg |

12 |

22 |

32 |

46 |

97 |

193 |

| Packing measurement |

cm |

23X18X23 |

28 X 21 X 27 |

32 X 21 X 29 |

40 X 21 X 35 |

50X41 X21 |

64 X 38 X 64 |

| Extra weight per meter extra lift |

kg |

1.7 |

2.3 |

3.7 |

5.6 |

9.7 |

19.4 |

OPERATION INSTRUCTIONS

Before lifting inspect carefully the hooks, the load chain, the brake device and lubrication of the block. For safe operation you must keep six rules as following.

1) Don't lift load exceeding the rated capacity of the chain block.

2) Don't use the block chain as a sling

3) Don't use when the chain is kinking.

4) To avoid accidents working or passing under a lifting load is strictly for bidden.

5) In case of the hand chain fails to move. Don't use undue force. Stop operation and proceed inspection of the chain block

6) Only use to lift vertically, do not use to drag loads.

MAINTENANCE

1. After operation, clean the chain block from dirt and keep it in a dry place from rust and corrosion.

2. Clean the chain block annually by purging the parts in kerosene and supply grease to them. It is advisable that the cleaning work should be done by skilled hands.

3. "O" marks on the two disk gears should be aligned.

4. Stick the rollers of both left and right bearings to the inner race of the bearings on the chain sprocket shaft journal, and then put then into outer race of the bearing on the side plates.

5. After cleaning and repair the chain block should be subjected to non-load and heavy load tests. If it works normally put it into operation.

6. For convenience of maintenance and dismantling. One of the links of the hand chain is open.

Lifting Load : Ensure area is clear of people and obstruction, and begin lifting by slowly pulling hand chain "U" direction.

Lowering Load : Ensure area is clear of people and obstruction, and reverse lifting procedure. It may be necessary to apply extra initial effort to release friction between brake components

|

|

|

|

|

|