|

|

|

|

|

|

a) Included angle more than 90o

b) Included angle not more than 90o

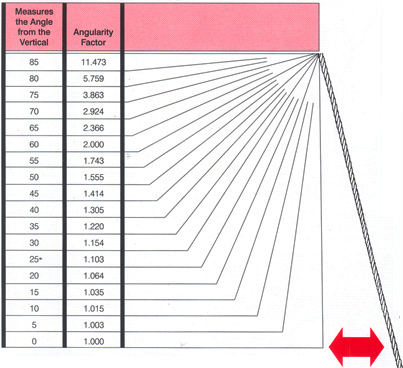

capacity charts for slings used in single part in this catalogue are given for vertical loading only. That is, zero angle from the vertical". Slings used in multiple parts, such as basket hitches and all multiple legged slings are given for bothyertical loading and for loading at 45 from the vertical. When a multiple part sling is to be used at some angle other than zero degrees or 45 from the vertical, the proper sling size can be chosen by applying the angularity factor shown in the above chart. |

How to Select the Proper Sling Size

How to Select the Proper Sling Size

1) Select the type of sling to be used.

2) Determine the maximum angle from the vertical atwhich the sling or any leg of the sling will be used.

3) Using this maximum angle, obtain the corresponding angularity factor the above chart.

4) Multiple this angularity factor by the total load to be lifted.

5) The result, which is the necessary strength required, is then referred to the vertical rated capacity chart of the selected ' type of sling. This will determine the proper sling size.

Example

A 10 ton load to be lifted at three points, Maximum vertical angle of legs will be 350. Angularity factor for 350 is 1.220. Multiply 1,220 times 10 tons for 12.20 tons. Choose a three leg sling where vertical rated capacity is at least 12.20 tons. Safety factor of 5 is already included in all tables.

Wire Rope Sling Inspection

An exact determination of when to retire a sling depends on many variable, and limited federal guidelines exist. Rather sling retirement (and safety factors) must be left to the judgement of a trained and experienced professional who is capable of evaluating remaining strength in the sling. Proper allowance must be made for deterioration as disclosed by inspection. The safety of an operating sling depends upon this remaining strength.

The following conditions must be taken into account when determinating the safe operating condition of a sling.

1) For strand laid and sling part slings, ten randomly distributed wires on one rope lay, or five broken wires in one strand in one rope lay.

2) For cable laid and braided slings of less than eight parts, twenty randomly distributed broken wired in one lay or braid, or one broken strand per sling.

3) For braided slings of eight parts or more, forty randomly distributed wires in one lay or two broken strands per sling.

4) Severe localized abrasion or scraping.

5) Kinking, crushing, bird caging or any other damage resulting in distortion of the wire rope.

6) Evidence of heat damage: if a wire rope sling having a fiber core is exposed to temperatures in excess of 200 F; or if a wire rope sling having an IWRC is used at temperatures above 400° F or below -60° F.

7) End attachments that are cracked, deformed or worn.

8) Hook that have been opened more than 15% of the normal throat opening measured at the narrowest point more than 100 from the plane of the unbent hook.

9) Corrosion of the rope or end attachments. |

| |

|

|

|

|

|