|

|

|

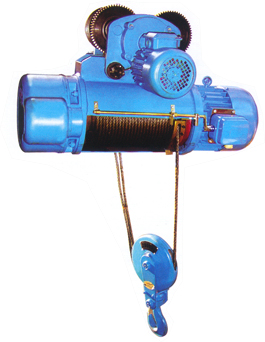

| With Motorised Trolley

|

CD 1 and MD 1 type of steel-rope electric hoist is a kind of small-sized lifting equipment which use steel-rope as flexible windlass. In this mechanism, the conic motor with reducer itself drives the roller to rotate through the reducer via the coupling instrument, then the steel-rope winded symmetrically on the roller can carry the suspension hook to raise and fall.

The hoist exists in form of two styles:one is the stationery (A1 ,A2,A3,A4 according to the position (up, down, left and right), the other is crab-style (B type). See picture 1 and picture 3 for details:

|

|

|

|

Picture 1: Cd1 type hoist of stationary, the lifting height is 6M - 30M

1. reducer

2. winding drum

3. hook

4. rape-guide

5. position-limit

6. single speed motor

|

Picture 2:

Cd1 type hoist of crab-style, the lifting height is 6M - 9M

1. reducer

2. winding drum

3. hook

4. rope-guide

5. dynamoelectric dolly

6. position-limiter

7. single speed motor

8. button switch

9. electric-controlling box

10. cable bracket

Picture 4:

Adjustment of the running distance for the main motor axis

1. rear cover

2. fan braking wheel

3. fan covering

4. bolt

5. regulation nuts.

|

|

Picture 3:

Reducer structure of the hoist

| 1. oil sprue |

12. oil seal 1 |

| 2. axletree 1 |

13. oil seal 2 |

| 3. box-cover |

14 axletree 4 |

| 4. 04 gear-axis |

15. 08 gear axis |

| 5. axletree 7 |

16 axletree 6 |

| 6. seal ring |

17 axletree 3 |

| 7. box-body |

18. 06gearaxis |

| 8. 09 gear |

19. 05 gear |

| 9. axletree 8 |

20. axletree 5 |

| 10. hollow spindle |

21. oil out hole |

| 11. axletree 2 |

22. 07 gear |

Md1 type is almost the same is structure with the Cd1 type, just that the single speed motor is replaced by double speed one, and that the electrical equipment is double speed control.

All reducers of CD 1 and MD 1 series of steel-rope electric hoist adopt 3-Level slanting gear. Get the details of reducer structure from picture 4, its parameters is in Table 1.

|

|

|

Technical data and exterior dimensions of series of steel-rope electric hoist.

The winding drum equipment is mainly consists of roller, steel-rope, rigid coupling and flexible coupling etc. It is made of cast-iron when the lifting height is 6M, 9M and 12M, and seamless steel when the height is above 12M.

Dynamoelectric dolly is the traveling machinist of the hoist. It is only used on crab-style;. The traveling mechanism is divided into two structure by its lifting height:one on condition that the height is 6M and 9M, the other when the height is 12M-30M.

The moment of the motor is passed to the reducer via claw-shaped coupling instrument, it adsorb the impact, so that the hoist can startup smoothly.

To avoid the trouble that the hook go beyond the position limit, there are position-limiter. When the hook get to the limit, the power will be cut off automatically.

Use and Maintenance:

Newly-installed steel-rope electric hoist should be tested with no load several times, It is not until there is no abnormal phenomenon occurring in the no-load test that the loading test can be conducted.

- In the lifting test, see whether the performance of every part is right.

- Qualified operator

- Healthy and have a knowledge of mechanics and electrical operation

- Familiar to electric hoist's structure, performance, safety rules and such illustration etc.

- Workwith training credential

- The braking motor should be adjusted to such an extent as the heavy object can stop in the air. When stop during the course if falling with regular load, the sliding distance S <= Vup/100mm(Vup short for lifting speed with regular load). When S > Vup/100mm, it is imported to make some adjustment.

- Operating rules

- Each shift should examine every day

- Do not stop via position-limiter or adjust brakes while lifting heavy objects, carry out examination or maintanance

- As the heavy objects approach or reach regular load, do try for a short distance and lift with the lowest height. Make sure there is nobody below when lifting objects

- 3 or more - circle steel-rope must be left on the roller on safety grounds when the hook is at the lowest working position for the electric hoist without falling position limiter.

- Do not remove the reassemble the safety devices on the electric hoists.

- Stop -> Check -> Eliminate troubles -> Restart, such a procedure should be obeyed when there is abnormal noise during the operation

|

|

|

|

|

|